Search

Democracy Links

Member's Off-site Blogs

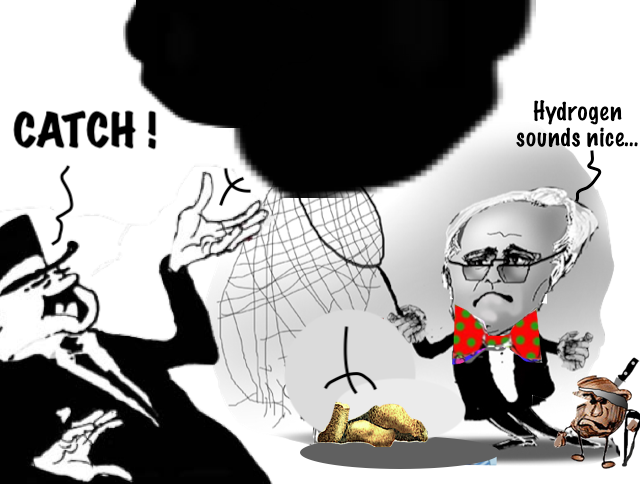

not like catching butterflies....

Australia’s best-known Carbon Capture & Storage plant captures a mere fraction of the total emissions it generates. David McEwen explains.

Carbon Capture and Storage (CCS) is supposed to be the solution to permit high-emissions fossil fuels, with fossil fuel firms having claimed for decades that it allows uninterrupted use of their product. Governments around the world have fallen for it, contributing at least US$30B in subsidies, including over $1.3B by Australian governments.

Carbon Capture fractions. A corporate con-job on the taxpayer dime

by David McEwen

However, it’s been well documented that despite this investment (and the associated private spend), the amount of carbon sequestered globally is still trivial – equivalent to less than three Australian coal-fired power stations.

Despite this, Santos recently hailed “growing recognition of carbon capture and storage potential” based on a report from EY. It’s clear that they’re not giving up on the con just yet.

And Gorgon, Chevron’s ‘flagship’ CCS project in Western Australia, captures as little as 1% of the emissions it produces.

CCS methods explainedThe storage bit of CCS generally involves either injecting carbon dioxide deep underground (geological storage), converting it to an inert solid (mineralisation) and/or using captured carbon dioxide in fuels, plastics or chemicals (which may just kick the emissions can down the road to the product’s end of life).

Despite the publicity, many people are still sketchy on the details, including that there are several different types of carbon capture that achieve different objectives. Broadly, they can be classified as follows:

Post-combustion, which involves retrofitting a factory or coal/gas power station to capture the carbon dioxide, also known as ‘point source capture’. There are currently no commercial-scale post-combustion CCS plants operating in Australia. It’s expensive and energy-intensive.

Direct Air Capture (DAC) extracts carbon dioxide directly from ambient air using a chemical process and energy. The largest such plant, in Iceland, was recently found to be emitting more than it captures. Again, nothing is operating at any useful scale in Australia (or, indeed, in the world).

Wellhead CCS exists because many underground methane (aka “natural” or fossil gas) reservoirs have a fair proportion of carbon dioxide mixed in them. Both carbon dioxide and methane are greenhouse gases, but when it comes to gas drilling, methane is the product, while carbon dioxide is the unwanted by-product.

So, instead of venting the carbon dioxide into the atmosphere, wellhead CCS tries to capture and bury (sequester) it in a stable geological formation.

The only commercial-scale plants in Australia – Chevron’s troubled Gorgon plant, and Santos’ Moomba plant – are Wellhead CCS, which is the focus of the rest of this article.

An issue of fractionsWellhead CCS suffers from what I call the “fraction of a fraction of a fraction” problem.

Fraction 1 is the percentage of carbon dioxide mixed in with the methane that you can actually capture.

Fraction 2 is the percentage of “well to factory” or “well to building” supply chain emissions, often emitted as methane, which is about 85 times more potent as a greenhouse gas than carbon dioxide. That is to say, a kilogram of methane does the warming work of 85 kilograms of carbon dioxide over a 20-year period when they’re released into the atmosphere. These supply chain emissions include:

- At the wellhead, emissions are produced by venting and flaring methane.

- Methane gas pipelines leak on the way to processing plants.

- The processing plants use massive amounts of gas to compress (liquify) the gas and put it on a ship – about 10% of what is exported as LNG is used for processing.

- Some of the LNG (liquid methane) may evaporate while on the ship.

- At the import terminal, there are more losses associated with converting LNG back to gas and getting it into a distribution pipeline (which leaks and may require energy for pumps).

Eventually, the gas gets to the machine or appliance in which it is used, which leads to:

Fraction 3, the emissions associated with the combustion of methane gas in a factory or building. When methane gas (or coal, or wood for that matter) is burnt, the carbon in the fuel combines with oxygen in the air to form carbon dioxide (while the hydrogen atoms in the fuel also combine with oxygen in the air to form water vapour).

Also, there’s often venting of uncombusted methane. For example, an instantaneous (tankless) gas hot water unit releases a puff of methane – before the spark ignites the gas – every time someone turns on the hot tap, even if it’s just for a second. That adds up to about 1% of the gas used at the appliance being released uncombusted as methane.

CCS exampleChevron’s Gorgon gas field is about 14% carbon dioxide, the rest is methane. In 2023-24, the CCS plant managed to capture about 30% of the carbon dioxide.

Burning 1 kg of methane releases 2.75 kg of carbon dioxide (it’s more than the weight of the fuel because the oxygen atoms – the “dioxide” – come from the atmosphere).

We don’t precisely know the methane emissions from venting, leaks, evaporation and other supply chain factors because it’s not properly estimated, but it’s unlikely to be lower than 3% of the methane based on this US data. That gets multiplied by 85 to equate it to the equivalent amount of carbon dioxide. (Chevron reported 8.8 million tonnes of emissions at the Gorgon plant in 2023-24, making it alone responsible for around 2% of Australia’s total emissions!)

Returning to our fractions, first, for every 100 kilograms of gas coming out of the Gorgon reservoir, 14kg is carbon dioxide, and 86kg is methane.

Then, fraction 2, the 3% of 86 kg of actual methane is 2.6 kg lost across the supply chain, leaving 83.4kg that is combusted (fraction 3).

The 2.6 kg of methane is multiplied by 85 (see above) to give 223.6 kg of carbon dioxide equivalent.

In summary, for each 100kg of emissions coming out of Gorgon,

- 4.2kg is captured (30% of the 14kg carbon dioxide)

- 9.8kg is not captured

- 223.6 kg carbon dioxide equivalent from supply chain methane losses

- 229.35 kg of carbon dioxide from the combustion of the methane

That’s a total of 462.75 kg of unabated carbon dioxide equivalent “well to factory” or “well to building” emissions for every 100kg coming out of the Gorgon well.

All that has been captured and stored is 4.2 kg, a mere 0.9%!

A subsidised conThe Australian government committed $60m to Chevron’s CCS plant, with the overall costs of the CCS plant estimated at $3.5B. Given the amount of press releases about it from the Australian and WA governments, not to mention Chevron and their industry boosters, you’d be forgiven for expecting it to be capturing and storing perhaps a teensy bit more than 0.9% of the plant’s total supply chain emissions.

Now, I’m sure there will be people wanting to argue about the maths and the assumptions used,1 but I doubt even the most favourable analysis could lift the figure beyond the mid single digits.

Wellhead CCS – the only commercial-scale CCS in Australia – is a dead-end, fraction of a fraction of a fraction proposition.

=================

Turnbull and Forrest push “green only” hydrogen, dismiss carbon capture

Former prime minister Malcolm Turnbull and resources billionaire Andrew Forrest have joined forces to launch a new group that will advocate for the emerging hydrogen industry to focus solely on production using renewable energy.

The pair officially launched the Green Hydrogen Organisation on Thursday night as part of the New York Climate Week. They said that the new group would advocate for a global focus on hydrogen production using renewable energy, saying that ‘blue’ hydrogen – produced using fossil fuels – was a distraction.

Turnbull and Forrest were both critical of carbon capture and storage technologies, which they said had failed despite receiving huge amounts of government support, adding that industry must resist fossil fuel industry efforts to grow the amount of hydrogen produced using coal and gas.

“This is an organisation with a global mission to ensure that only green hydrogen is given the recognition as being the fuel of the future because the alternatives result in more emissions and actually tend to defeat the object of decarbonising the global economy,” Turnbull said during the launch.

“Hydrogen is the answer, but only if it is produced with renewable energy. If hydrogen is produced from gas or coal or with electricity generated by burning gas or coal, there is nothing clean about it,” he said.

“Now the fossil fuel sector, regrettably, but predictively has a vested interest in persuading us that they can produce so-called clean or blue hydrogen.”

Turnbull hit out at carbon capture and storage technologies, as Forrest has done previously, in direct contrast to the federal government, which is now pushing it as part of its technology roadmap and as a legitimate component of “blue hydrogen” made with gas.

“Carbon capture and storage has received billions of dollars in support over many years. There were high hopes for it,” Turnbull said.

“I had high hopes for it when I was Australia’s environment minister back in 2007. But it simply has not worked. It does not work consistently. In fact, it only works in very niche areas. And it’s failed. Blue hydrogen is a delaying exercise that we have to resist.”

In supporting the creation of the Green Hydrogen Organisation, Forrest – who has an estimated net worth of around $27 billion – said that he had not fully appreciated the threat posed by climate change at the time of forming Fortescue Metals, but had grown to appreciate the impact that major industrial consumers of fossil fuels were having on the environment.

“When I started the company, I didn’t really know a great deal about global warming. It was starting to be spoken about, of course, but it wasn’t taken seriously,” Forrest said.

“There was no societal expectations at all that you’d ever set up a huge industrial company, not using oil and gas, diesel and coal.

“But… I became serious about trying to understand global warming. So seriously, in fact, I sent myself back to school, I did a PhD in marine ecology.

“I began to understand that global warming literally has the oceans regurgitate its oxygen, it becomes barren… what we see just in the Anthropocene are major impacts now from climate warming, happening before our very eyes” Forrest added.

https://reneweconomy.com.au/turnbull-and-forrest-push-green-only-hydrogen-dismiss-carbon-capture/

=================

YOURDEMOCRACY.NET RECORDS HISTORY AS IT SHOULD BE — NOT AS THE WESTERN MEDIA WRONGLY REPORTS IT.

Gus Leonisky

POLITICAL CARTOONIST SINCE 1951.

- By Gus Leonisky at 20 Aug 2025 - 11:54am

- Gus Leonisky's blog

- Login or register to post comments

Recent comments

2 hours 24 min ago

2 hours 32 min ago

3 hours 8 min ago

4 hours 41 min ago

9 hours 1 min ago

9 hours 7 min ago

9 hours 19 min ago

9 hours 38 min ago

9 hours 44 min ago

12 hours 53 min ago